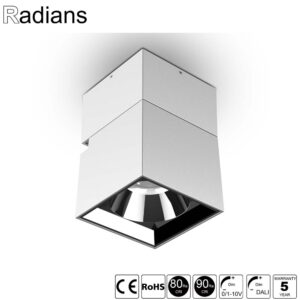

COB (Chip on Board) LED Technology

COB LEDs feature multiple LED chips bonded directly to a substrate to form a single module. This design allows for a higher concentration of light sources in a smaller area, resulting in a more intense and uniform light output. COB downlights are known for their excellent thermal performance and high light intensity, making them ideal for applications requiring focused and powerful illumination.

Advantages and disadvantages

COB Downlights

| Feature | Advantages | Disadvantages |

|---|---|---|

| Light Output | High intensity, focused beam, excellent for accent lighting | Can produce harsh shadows, may require additional diffusion |

| Thermal Management | Efficient heat dissipation due to direct bonding to the substrate | Higher heat concentration requires robust heat sinks |

| Color Rendering | Can achieve high CRI with proper design | Requires careful design to maintain color uniformity |

| Efficacy | Can be efficient, but often requires a trade-off with light intensity and thermal management | Increasing drive current can reduce efficacy and increase heat generation |

| Cost | Higher cost due to complex design and specialized components | May not be cost-effective for general lighting applications |

| Lifespan | Long lifespan with proper thermal management | Requires careful attention to heat sink design and airflow |

| Applications | Accent lighting, retail displays, architectural lighting, stage lighting | Not ideal for general lighting where uniform illumination is desired |

| Additional Considerations | Ideal for spotlighting and creating dramatic effects, enhancing visual appeal in specific areas | May require more energy to achieve the same level of ambient brightness as SMD downlights |

The Future of Downlight Technology

As LED technology continues to advance, both COB and SMD downlights are expected to evolve and improve. Some potential future trends include:

- Higher Efficacy: Continued improvements in LED chip technology will lead to higher efficacy and lower energy consumption for both COB and SMD downlights.

- Smarter Controls: Integration with smart home systems and advanced lighting controls will enable more personalized and energy-efficient lighting solutions. Learn more about the future of the smart lighting market on Radians Lighting’s website.

- Improved Color Rendering: Advancements in phosphor technology will result in even higher CRI values and more accurate color reproduction for both COB and SMD downlights.

- Sustainable Materials: Increased use of sustainable and recyclable materials in the manufacturing of downlights will contribute to a more circular economy and reduce environmental impact. You can explore circular economy lighting and sustainable lighting solutions on Radians Lighting’s website.

In summary, COB and SMD downlights each offer unique advantages and are suited for different applications. COB downlights excel in providing intense, focused light for accent lighting and retail displays, while SMD downlights offer diffused, uniform light for general illumination. The choice between the two depends on the specific lighting needs, budget, and design preferences.

As you consider your lighting options, remember that Radians Lighting offers a wide range of high-quality, customizable downlights to meet your specific requirements. With a commitment to innovation, design, and quality control, Radians Lighting is your trusted partner for creating exceptional lighting solutions. By understanding the nuances of COB and SMD technology and partnering with a reputable manufacturer like Radians Lighting, you can create lighting designs that are both functional and aesthetically pleasing, enhancing the ambiance and efficiency of any space.