LED-downlights er blevet den foretrukne belysningsløsning i hele Europa og er værdsat for deres energieffektivitet, lange levetid og moderne design. Den sande ydeevne og pålidelighed af disse produkter afhænger dog af én kritisk faktor: effektiv varmeafledningUden robust temperaturstyring kan selv de mest avancerede LED-downlights svigte for tidligt, miste lysstyrke eller udgøre sikkerhedsrisici. Denne omfattende artikel undersøger, hvorfor varmeafledning er afgørende i design af LED-downlights, dykker ned i videnskaben og teknikken bag det og fremhæver, hvordan... Radians belysning fører branchen med streng kvalitetskontrol og innovation.

Forståelse af varmegenerering i LED-downlights

Hver LED-downlight genererer varme under drift, et biprodukt af den elektriske energi, der driver lyskilden. Selvom LED'er er langt mere effektive end traditionelle glødepærer, omdanner de stadig en del af energien til varme – primært ved halvlederforbindelsen på LED-chippen. Hvis denne varme ikke styres, akkumuleres den i downlight'en, hvilket fører til termisk stress og gradvis nedbrydning af LED-materialerne.

Nøglepunkt: For hver 10°C stigning i LED-forbindelsestemperaturen kan LED'ens levetid reduceres med op til 50%. Denne dramatiske effekt understreger, hvorfor varmehåndtering ikke kun handler om komfort, men om produktets grundlæggende ydeevne og holdbarhed.

Varmeafledning: Mere end blot skaltemperatur

Mange tror fejlagtigt, at temperaturen på downlightens ydre skal er den største bekymring. I virkeligheden... de interne temperaturer i lyskilden, driveren og de elektroniske komponenter—herunder IC'er og kondensatorer — er de sande faktorer, der bestemmer produktets levetid og ydeevne.

- LED-chip (lyskilde): Halvlederforbindelsen er der, hvor der genereres mest varme. For meget varme her forkorter LED'ens levetid og kan forårsage farveskift.

- Chauffør: Driveren regulerer strømmen og indeholder følsomme elektroniske dele. Hvis den overopheder, kan det forårsage flimmer, reduceret effektivitet eller fuldstændig fejl.

- Kondensatorer og IC'er: Disse komponenter er særligt følsomme over for varme. Langvarig eksponering fremskynder aldring og risikerer pludselige nedbrud.

Brancheindsigt: Intern varmeophobning forårsager kemiske og mekaniske nedbrud, hvilket fører til hurtig lumenforringelse og farveustabilitet. For eksempel kan en kondensators levetid halveres for hver 10°C temperaturstigning.

Varmeaflednings rolle i LED-downlightdesign

Effektiv varmeafledning opnås gennem en kombination af designvalg og materialevalg:

- Køleplader: Disse strukturer er normalt lavet af aluminium på grund af dets høje varmeledningsevne, og de trækker varme væk fra LED-chippen og andre komponenter.

- Termiske grænsefladematerialer: Puder, fedt eller klæbemidler forbedrer varmeoverførslen fra LED'en og driveren til kølepladen.

- Ventilation og luftstrøm: Veldesignede huse tillader luftcirkulation og forhindrer varmeophobning.

- Driver- og kredsløbsdesign: Effektive drivere genererer mindre varme og er bygget til at modstå højere temperaturer.

Et korrekt konstrueret system sikrer, at alle kritiske komponenter forbliver inden for sikre temperaturgrænser, hvilket understøtter en stabil lysudbytte og forlænger produktets levetid.

Udfordringer ved varmestyring i LED-downlights

Design til optimal varmeafledning er komplekst, især i takt med at europæiske forbrugere kræver stadigt slankere og mere stilfulde downlights. De vigtigste udfordringer omfatter:

- Kompakt størrelse: Begrænset plads begrænser størrelsen af køleplader og luftstrømskanaler.

- Æstetiske krav: Varmestyring skal integreres uden at gå på kompromis med det minimalistiske udseende.

- Installationsmiljøer: Forskellige lofttyper, isolering og omgivelsestemperaturer påvirker den termiske ydeevne.

- Materialebegrænsninger: Letvægtsmaterialer er nemmere at installere, men leder muligvis ikke varme lige så effektivt.

Producenter skal afbalancere disse faktorer ved at bruge avancerede materialer og innovativ teknik for at sikre både form og funktion.

Producenter skal afbalancere disse faktorer ved at bruge avancerede materialer og innovativ teknik for at sikre både form og funktion.

Omfattende varmeafledning: Temperaturen i de indvendige komponenter har betydning

Det er vigtigt at erkende, at Effektiv varmeafledning handler ikke kun om at holde den ydre skal køligTemperaturerne på LED-chippen, driveren og de elektroniske komponenter er de reelle indikatorer for produktets tilstand. Hvis nogen af disse overstiger deres nominelle grænser, er hele downlightens ydeevne og sikkerhed i fare.

| Komponent | Sikker driftstemperatur (°C) | Virkninger af overophedning |

|---|---|---|

| LED-chip | < 95 | Lumen tab, farveskift, tidlig svigt |

| Chauffør | < 70 | Flimmer, reduceret effektivitet, nedlukning |

| Kondensator | < 105 | Hurtig aldring, pludseligt nedbrud |

| IC | < 100 | Funktionsfejl, ustabilitet |

Faktum: Mange fejl, der tilskrives "lampeudbrænding", skyldes faktisk overophedning af interne komponenter, ikke temperaturen i skallen.

Radians Lighting: Sætter standarden for varmeafledning

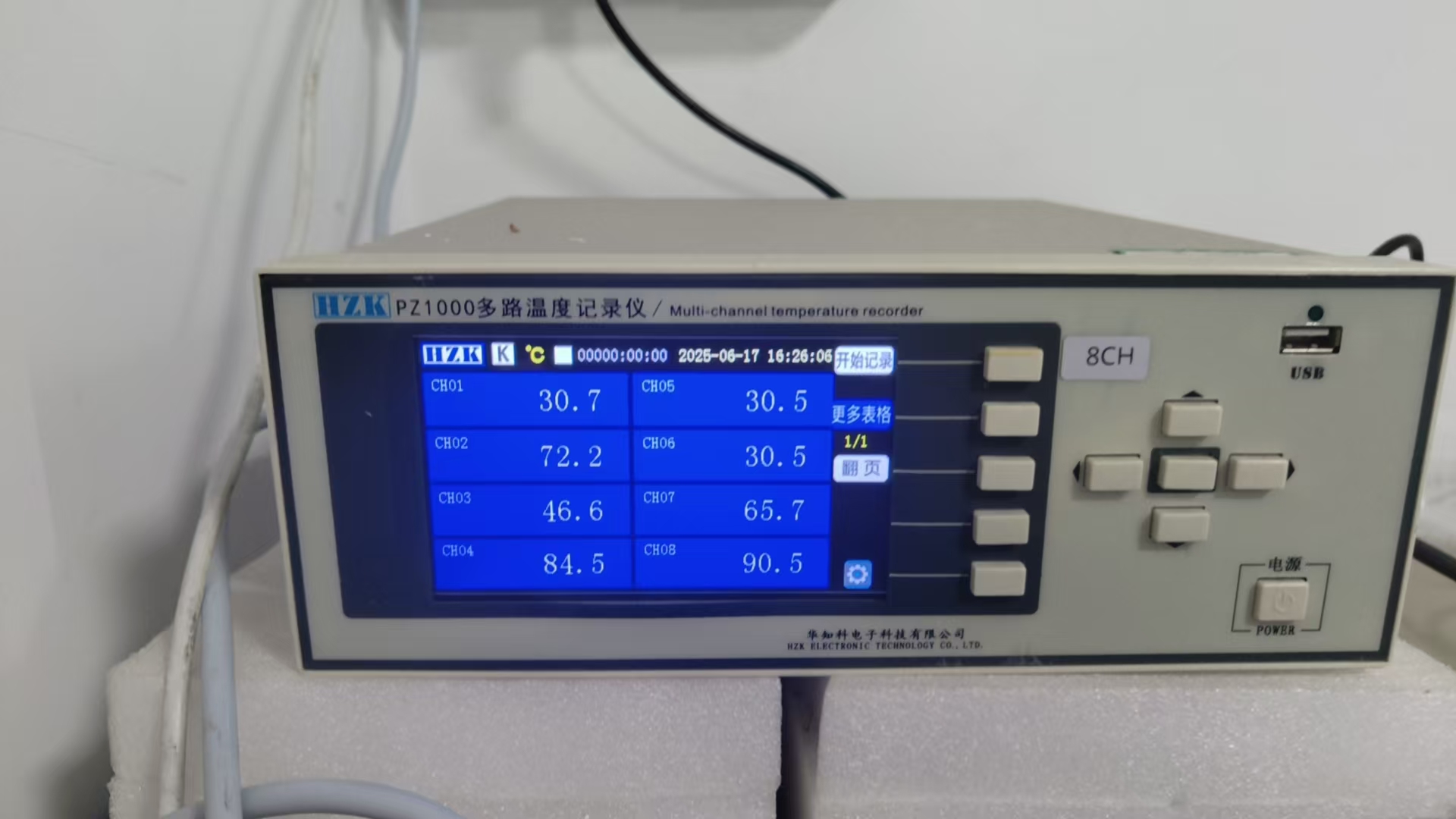

Radians Lighting skiller sig ud på det europæiske marked for sine stringent tilgang til varmeafledningHvert nyt produkt gennemgår temperaturstigningstest i et kammer med konstant temperatur, der simulerer virkelige forhold for at sikre, at alle interne komponenter forbliver inden for sikre grænser.

Radians' produkttilpasning og kvalitetskontrol

Radians tilbyder et bredt udvalg af LED-downlights, herunder:

Hver model er konstrueret med Tilpassede køleplader, optimerede driverkredsløb og førsteklasses termiske grænsefladematerialerRadians tilbyder også skræddersyede løsninger til unikke installationer, såsom overflademonteret, miniature, og smarte downlights.

Produktionskvalitetskontrol

Produktionskvalitetskontrol

Radians' engagement i kvalitet er tydeligt i deres:

- Termisk testning: Hvert nyt design underkastes temperaturstigningstests i et kontrolleret miljø.

- Komponentvalg: Der anvendes kun kondensatorer, IC'er og LED'er af høj kvalitet, som hver især er klassificeret til udvidet temperaturtolerance.

- Designoptimering: Finnestrukturer og termiske veje simuleres og testes for maksimal effektivitet.

- Overholdelse: Produkterne opfylder eller overgår europæiske sikkerheds- og energistandarder, herunder CE og RoHS.

Lær mere om Radians' produktionsproces og kvalitetskontrol på LED Downlight Factory.

Sammenlignende analyse: Varmeafledningsfunktioner i Radians LED-downlights

| Modelnavn | Køleplademateriale | Kølepladedesign | Drivertype | Vigtig termisk funktion | Prisinterval (EUR) |

|---|---|---|---|---|---|

| 6W LED downlight | Aluminium | Finnet, kompakt | Isoleret | Termisk pude, luftstrømsåbninger | 25 – 40 |

| COB Downlight | Aluminium | Store integrerede finner | Ikke-isoleret | Termisk fedt, stort kontaktområde | 40 – 60 |

| Dæmpbar Downlight | Aluminium | Høje overfladefinner | Triac dæmpbar | Forbedret varmebane, robust driver | 35 – 55 |

| Ultratynd downlight | Aluminiumlegering | Spredte finner | IC-driver | Tynd profil, klæbende grænseflade | 30 – 50 |

| IC-klassificeret downlight | Aluminium | Dyb, flerfinnet | IC-driver | Brandsikker, dobbeltisolering | 45 – 70 |

Se hele udvalget på Radians LED Downlight Kategori.

Videnskaben bag radianernes varmeafledningstest

Radians Lightings designproces omfatter test af temperaturstigning for hvert nyt produkt. I disse tests anvendes downlights i et kammer med konstant temperatur, der efterligner virkelige installationsforhold. Sensorer måler temperaturen ved LED-chippen, driveren og de vigtigste elektroniske komponenter.

- Hvorfor det er vigtigt: Dette sikrer, at selv i udfordrende miljøer overstiger ingen komponent den nominelle temperatur.

- Resultat: Produkterne leverer stabil lysstyrke, farve og levetid – understøttet af reelle data, ikke blot teoretiske påstande.

Ved at kontrollere de indvendige temperaturer garanterer Radians, at deres downlights fungerer pålideligt i årevis, selv i krævende europæiske installationer.

Indvirkning af varmeafledning på downlights ydeevne

Korrekt varmeafledning giver målbare fordele:

- Levetid: Downlights med effektiv varmestyring kan holde i over 50.000 timer.

- Lyskvalitet: Stabile temperaturer bevarer farvekonsistensen og forhindrer flimmer.

- Energieffektivitet: Køligere LED'er fungerer med højere effektivitet, hvilket reducerer strømregningen.

- Sikkerhed: Lavere indvendige temperaturer reducerer risikoen for brand og elektriske fejl.

Omvendt fører dårlig varmehåndtering til:

- Flimmer og dæmpning

- Farveskift og ujævn belysning

- Hyppig vedligeholdelse og udskiftning

- Højere risiko for katastrofale fejl

Bedste praksis for varmeafledning i LED-downlightdesign

For at sikre optimal ydeevne bør producenter og købere overveje følgende:

- Vælg materialer med høj varmeledningsevne (som aluminium) til køleplader.

- Maksimer overfladearealet med finner eller spredte køleplader.

- Brug termiske grænsefladematerialer af høj kvalitet for at forbedre varmeoverførslen.

- Optimer luftstrømmen i downlightet og installationshulrummet.

- Vælg robuste drivere, der er klassificeret til brede temperaturområder.

- Udfør temperaturstigningstest på alle nye produkter.

- Sikre overholdelse af europæiske sikkerheds- og energiforskrifter.

Radians Lighting inkorporerer alle disse praksisser i sin design- og fremstillingsproces.

Radians Lighting: Produktsortiment og anvendelseseksempler

Radians tilbyder et omfattende udvalg af LED-downlights, der hver især er designet med avanceret varmestyring til specifikke behov:

- 240V LED DownlightTil direkte tilslutning til europæisk netspænding.

- Sorte downlightsStilfuld finish med robust temperaturkontrol.

- Kommercielle LED downlightsHøjtydende modeller til kontorer og detailhandel.

- Mini LED downlightsKompakt, diskret og termisk optimeret.

- Overflademonteret LED downlightsTil installationer hvor indbygget montering ikke er mulig.

- IC-klassificerede downlightsSikker at installere med isoleringskontakt.

Udforsk mere på Radians LED Downlight Produktkategori.

Hvorfor europæiske købere stoler på Radians Lighting

Radians Lightings fokus på termisk styring, produkttilpasning og streng kvalitetskontrol har gjort det til en foretrukken leverandør i Tyskland, Frankrig, Holland, Sverige, Danmark, Norge og Storbritannien. Deres produkter er konstrueret til europæiske installationsstandarder, overholder lokale regler og opfylder de europæiske brugeres designpræferencer.

Radians' løbende investering i forskning og udvikling sikrer, at deres downlights forbliver på forkant med teknologi og sikkerhed. Deres transparente testprotokoller og engagement i kundetilfredshed afspejles i deres voksende markedsandel og positive anmeldelser fra belysningsprofessionelle.

Konklusion

Varmeafledning er fundamentet for pålideligt og højtydende LED-downlightdesign. Det påvirker alle aspekter af produktet, lige fra energieffektivitet og lyskvalitet til sikkerhed og levetid. Effektiv temperaturstyring kræver en holistisk tilgang – der ikke kun tager højde for den ydre skal, men også de indre temperaturer i LED-chippen, driveren og alle elektroniske komponenter.

Radians Lighting eksemplificerer branchens bedste praksis med grundige temperaturstigningstest, avancerede materialer og kvalitetskontrol i alle faser. Deres brede udvalg af produkter, skræddersyet til de europæiske markeder, sikrer, at købere kan finde den ideelle løsning til enhver anvendelse – i trygge hænder, velvidende at hver downlight er bygget til at holde.

For belysningsprofessionelle, arkitekter og slutbrugere er det afgørende at vælge LED-downlights med dokumenteret varmeafledning for at opnå bæredygtig, effektiv og sikker belysning i 2025 og fremover.

For at lære mere eller udforske Radians Lightings fulde produktsortiment, besøg den officielle hjemmeside på radianslighting.com.